An exclusive modular software for the Management and control of the production Cycle

compatible with all ERP SOFTWARE CPU SOFTWARE PLC SOFTWARE

What is CONNEXT?

CONNEXT is a MES (Manufacturing Execution System)

a GenX software for industrial process digitalization, custom-built depending on business demands.

CONNEXT allows you to monitor every single phase of the production cycle by collecting and analyzing data from the machinery, coordinating the phases and actions, all while managing resources ranging from raw materials, energy

sources and working hours.

A MES is a built-in system in business management that monitors machinery, materials and operations.

It follows the entire production cycle, starting from the launch of the work order to the completion of the cycle, up to the storage of the semi-finished product, until the finished product.

By using the materials, people and resources involved in the production cycle so effectively, it is no wonder that thanks to a MES software, companies are able to drastically increase levels of efficiency and sustainability when it comes to emission reduction, natural resource protection, and waste production reduction.

CONNEXT is developed and distributed by Nexto.

key functions

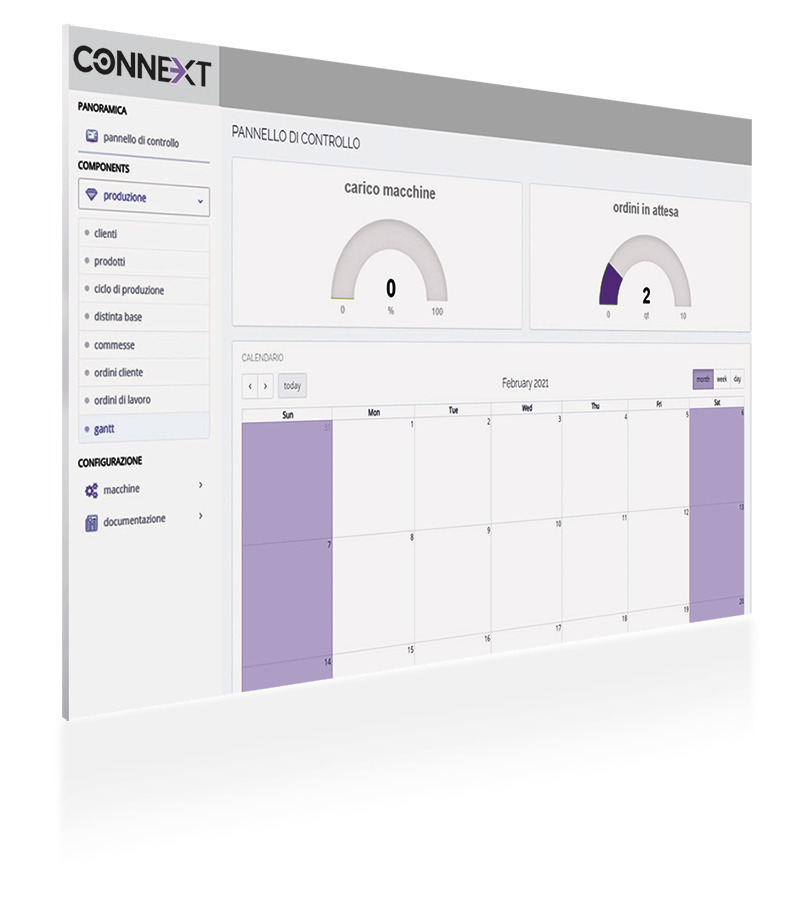

OEE supervision and tracking

Production tracking

Quality control and machining

Performance analysis

Data processing and collection

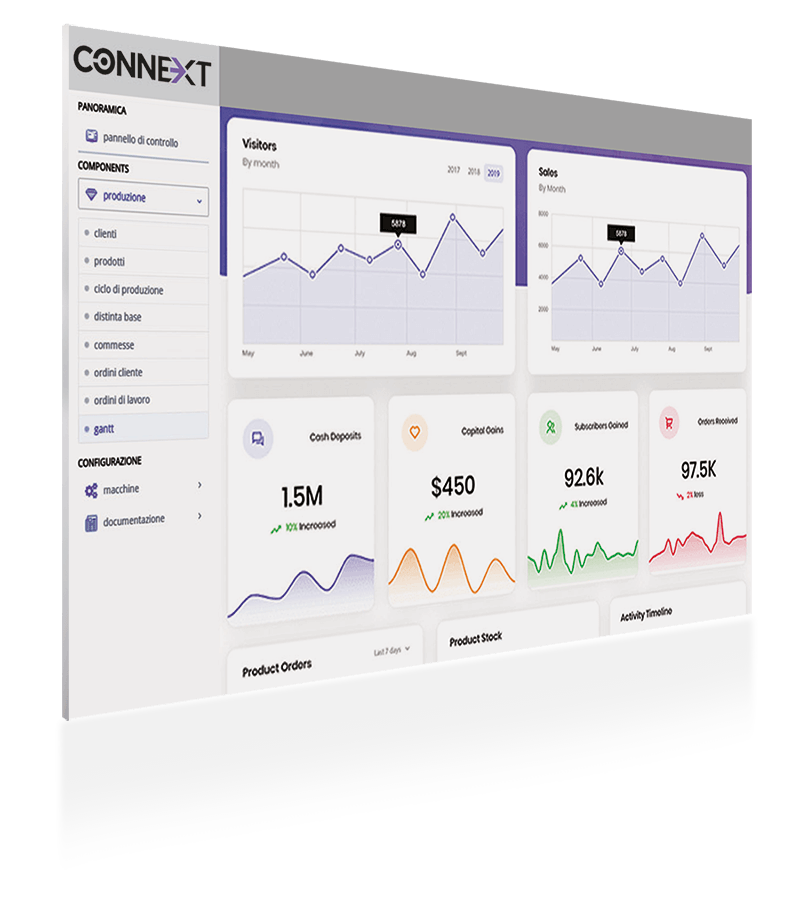

How CONNEXT works

CONNEXT was designed thanks to the outstanding collaboration between automation process and production cycle experts, starting from a focus on their daily needs. And it is precisely for this reason, that Connext offers a fully modular solution that guarantees a 360 ° management of the company production, interfacing with any ERP and PLC CPU either already installed or to be installed.

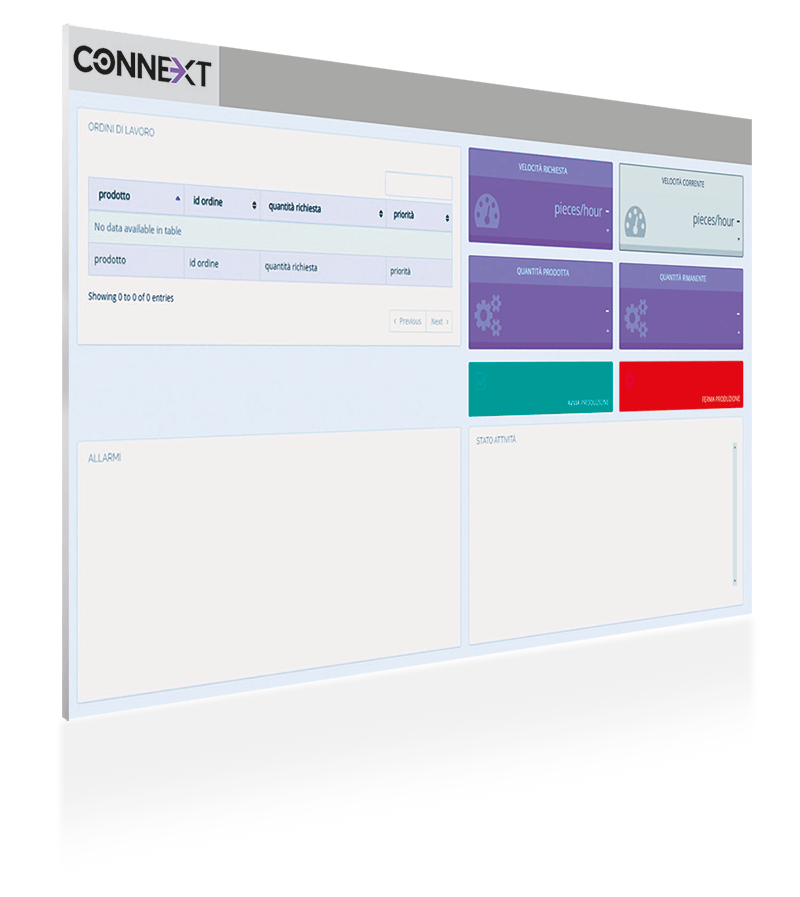

The user friendliness and functionality are the core features of this innovative WebAPP, which can also be used remotely, with any device

Digital transformation

CONNEXT consists of 6 accessible modules, which may also to be used individually, but that most importantly, are able to completely control the business production flows.

CONNEXT is involved not merely in the production realm, but especially

in the business management departments, for productivity and operating plant

and machinery status monitoring.

Practical assistance for secured access to state incentives

Thanks to the support of highly qualified and certified resources, Nexto Group guarantees the supply of simple or sworn expertise for the complete management of the bureaucratic cycle, required in order to access the incentives allocated at a governmental level.

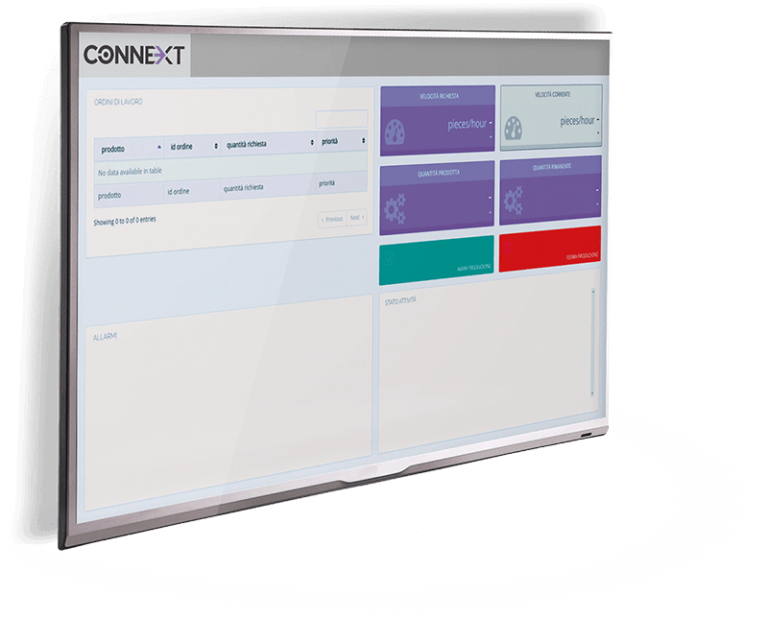

Monitoring production

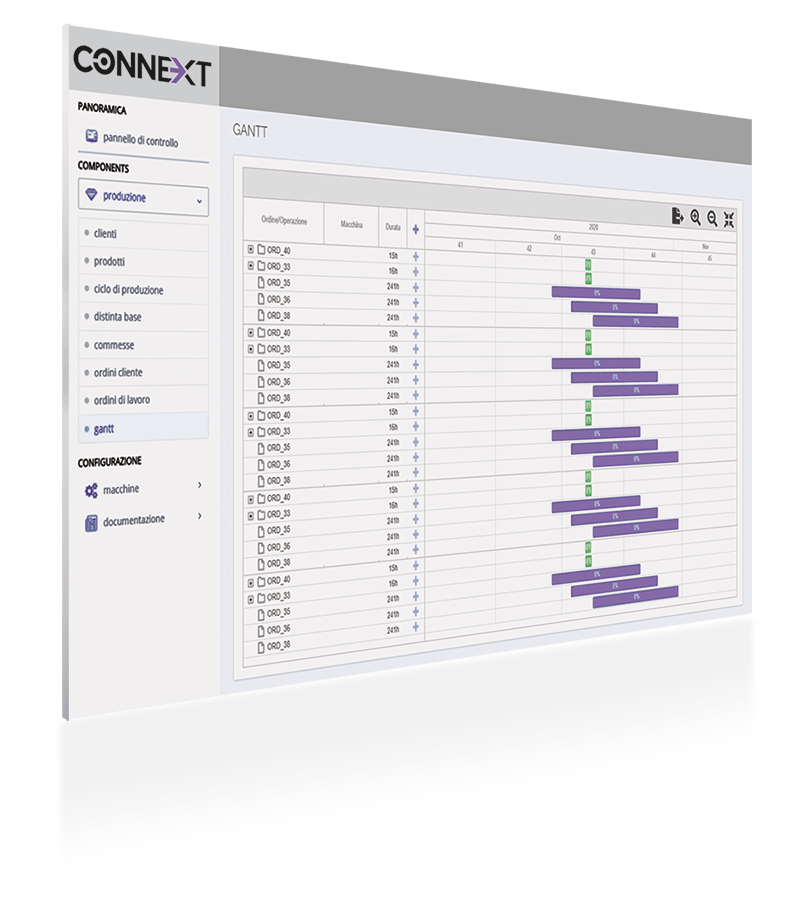

Planning & scheduling

Materials management

Quality control

Maintenance & surveillance

H2M Connector a universal multimachine & multi-protocol

So powerful that it makes it easy!

PRODUCTION CONTROL, WORLDWIDE

COMPLETELY CONNECTED

Thanks to the universal H2M module (Human to machine), Connext provides a complete service, offering itself as an exclusive and innovative built-in and universal solution.

A single supplier, with no issues.

MORE EFFICIENCY, LOWER COSTS

EASY TO PLAN

Incentives for the Industry 4.0

With the arrival of the new 2021 Budget Law, rates have risen, as well as incentives to support corporate digital transformation processes.

Investing in capital goods (hardware and software), foresees a possible a tax credit recovery of up to 50% of the investment as a substitute for hyper amortization. Additionally, there are also bonuses available for training activities, research, design and technological innovation.

Connext transforms this into reality.

Request a free Demo

DIRECTION

FUTURE

Nexto Group, leader in the design and management of processes, infrastructures, systems, applications and technologies related to all areas of industrial automation is the perfect solution for Industry 4.0